11 Most Sustainable Woods for Construction: A Life-Cycle Analysis

Impactful Ninja is reader-supported. When you buy through links on our site, we may earn an affiliate commission.

Learn more

Learn more

.

Hey fellow impactful ninja ? You may have noticed that Impactful Ninja is all about providing helpful information to make a positive impact on the world and society. And that we love to link back to where we found all the information for each of our posts. Most of these links are informational-based for you to check out their primary sources with one click. But some of these links are so-called "affiliate links" to products that we recommend. First and foremost, because we believe that they add value to you. For example, when we wrote a post about the environmental impact of long showers, we came across an EPA recommendation to use WaterSense showerheads. So we linked to where you can find them. Or, for many of our posts, we also link to our favorite books on that topic so that you can get a much more holistic overview than one single blog post could provide. And when there is an affiliate program for these products, we sign up for it. For example, as Amazon Associates, we earn from qualifying purchases. First, and most importantly, we still only recommend products that we believe add value for you. When you buy something through one of our affiliate links, we may earn a small commission - but at no additional costs to you. And when you buy something through a link that is not an affiliate link, we won’t receive any commission but we’ll still be happy to have helped you. When we find products that we believe add value to you and the seller has an affiliate program, we sign up for it. When you buy something through one of our affiliate links, we may earn a small commission (at no extra costs to you). And at this point in time, all money is reinvested in sharing the most helpful content with you. This includes all operating costs for running this site and the content creation itself. You may have noticed by the way Impactful Ninja is operated that money is not the driving factor behind it. It is a passion project of mine and I love to share helpful information with you to make a positive impact on the world and society. However, it's a project in that I invest a lot of time and also quite some money. Eventually, my dream is to one day turn this passion project into my full-time job and provide even more helpful information. But that's still a long time to go. Stay impactful,Affiliate Disclosure

Why do we add these product links?

What do these affiliate links mean for you?

What do these affiliate links mean for us?

What does this mean for me personally?

![]()

Wood is generally a sustainable building material, largely thanks to carbon uptake by timber trees. Woods are renewable, though renewing rates vary among tree species. Some woods travel a long distance to reach construction sites, and if they are heavy hardwoods, these transporting miles make a sizable impact on the overall carbon footprint. So we have to ask: Which woods are the most sustainable for construction?

The most sustainable softwoods for construction are slash pine, bald cypress, and Douglas fir – fast-growing lumber with high strength-to-weight ratios. The most sustainable hardwoods for construction are black cherry and black locust – highly available lumber with great absolute strength.

In this article, we will walk you through the life-cycle of the most sustainable kinds of wood for construction. Then, we evaluate their sustainability, potential, and shortfalls. We will also investigate the possibilities of using tropical hardwoods and engineered (composite) wood panels for building houses and other structures. And in the end, we’ll show you tips for buying sustainable woods for construction.

Here’s How We Assessed the Sustainability of All Types of Wood for Construction

In general, wood is a sustainable material because of timber trees’ carbon sequestration potential and the carbon offset value at the end of the wood product’s life-cycle.

“Sustainable: The ability to be maintained at a certain rate or level | Avoidance of the depletion of natural resources in order to maintain an ecological balance”

Oxford Dictionary

However, some woods are better than others for building houses and other structures. One way of assessing the sustainability of construction lumber is to go through their life-cycles and evaluate each stage’s sustainability. This life-cycle assessment (LCA) is a method to assess the environmental impacts of products and materials. Over the years, companies have strategically used LCA to research and create more sustainable products. So, let’s look at the LCA of some of the most sustainable woods for construction.

In this article, we’ll use the cradle-to-grave perspective of the LCA, examining the five stages of the life-cycle of woods used for buildings. Where it is relevant, we also use data from cradle-to-gate assessments.

These five stages of the life-cycle of construction lumber are as follows:

- Growing of the tree for lumber harvesting

- Manufacturing of construction lumber

- Transportation of construction lumber

- Usage of construction lumber

- End-of-life of construction lumber

The life-cycle assessment typically covers some or all of the following environmental impacts:

- Global warming potential

- Primary energy demand from resources

- Acidification potential

- Freshwater eutrophication potential

- Marine eutrophication potential

- Photochemical ozone creation potential

- Resource depletion

The global warming potential impact reflects the risk of accelerating climate change through the emissions of greenhouse gases. It focuses on CO2 and other greenhouse gasses (CH4, nitrous oxide, and chlorofluorocarbons) released throughout a product’s life-cycle. This impact is measured in kg of CO2 equivalent emitted per unit of a product – the carbon footprint.

“Carbon footprint: the amount of greenhouse gases and specifically carbon dioxide emitted by something (such as a person’s activities or a product’s manufacture and transport) during a given period”

Merriam Webster

Deciding factors for (high or low) carbon emissions during construction lumber’s life-cycle are:

- Drying requirements of timber

- Distribution of timber trees

As trees grow, they sequester carbon dioxide from the atmosphere. The carbon uptake can often compensate fully for carbon emitted during all the stages of the life-cycle. It indicates a negative carbon balance, which is environmentally favorable. The lower the carbon balance stays below zero, the better it is for the climate. Relevant factors to the actual carbon balance of woods are:

- Tree sizes

- Tree growth rate

- Natural durability

In this article, we’ll specifically zoom into species’ growth rate, tree size, distribution, woodworking properties, and natural durability, as these are the deciding reasons behind the carbon balance of woods.

We will also look into how to make a more sustainable choice when using tropical hardwoods and engineered (composite) wood panels to build your home.

These Are the 11 Most Sustainable Types of Wood for Construction

These woods are relatively strong and naturally durable. Thanks to their large populations in the US, they can be harvested sustainably and transported to construction sites at relatively low carbon emissions (compared to tropical hardwoods or other building materials). Most importantly, the plain-sawn lumber form of these woods has an environmentally favorable carbon balance (aka more carbon uptake than carbon emission).

| Type of wood | Overall sustainability |

| Slash pine wood | What makes it so sustainable: Slash pine and other southern yellow pines are the strongest, by quite a margin, of all US softwoods. Its exceptional strength keeps it last longer as carbon storage, extending the environmental benefit from carbon uptake during forestry. Additionally: Slash pine has a sustainable population across the southeastern US, largely thanks to the species’ fast growing rate and adaptation to even the more challenging sites |

| Bald cypress wood | What makes it so sustainable: Bald cypress has excellent strength and decay resistance. And because of its natural durability, the wood is seldom treated with preservatives, meaning it can be fully recycled or burned for bioenergy. Additionally: Bald cypress has a relatively low transporting carbon footprint thanks to its lightweight. |

| Douglas fir wood | What makes it so sustainable: Douglas fir trees are abundant in North America (~20% of all softwood reserves). Also, they grow relatively fast and extremely tall, quickly replenishing any timber cut. Additionally: Douglas fir is one of the strongest Western softwood species. It also has a natural resistance to decay. |

| Sitka spruce wood | What makes it so sustainable: Sitka spruce is highly durable thanks to an excellent strength-to-weight ratio. Also, spruce timber is highly available thanks to the large population, the quick growth and the enormous tree size. Additionally: Sitka spruce dries quickly, resulting in a relatively low manufacturing carbon footprint. |

| Nootka cypress wood | What makes it so sustainable: Nootka cypress has excellent stability, strength, and decay resistance. And because of its natural durability, the wood is seldom treated with preservatives, meaning it can be fully recycled or burned for bioenergy. Additionally: Nootka cypress is among the strongest US softwoods, making it a durable building material. |

| Western red cedar wood | What makes it so sustainable: Western red cedar wood is a highly available construction lumber. It also has good rot and pest resistance. Additionally: Western red cedar is light and, once dried, dimensionally stable lumber, which is ideal for various types of building structures. |

| Western larch | What makes it so sustainable: Western larch is highly replenishable lumber because these conifers grow rapidly – faster than other softwoods like Douglas fir and spruce. Additionally: Western larch is one of the hardest softwoods from the US forests, meaning it can last longer than many other softwoods in construction projects. |

| Black cherry wood | What makes it so sustainable: Black locust trees grow fast and can regrow even more faster after cutting, replenishing timber cut for woodworking. Also, exterior structures made with black locusts can last for many decades, extending its role as carbon storage. Additionally: Black locus is a domestic hardwood, and thus, it has a lower transporting carbon footprint than imported tropical hardwoods. |

| Black locust wood | What makes it so sustainable: Black locust trees grow fast and can regrow even faster after cutting, replenishing timber cut for woodworking. Also, exterior structures made with black locusts can last for many decades, extending their role as carbon storage. Additionally: Black locus is a domestic hardwood, and thus, it has a lower transporting carbon footprint than imported tropical hardwoods. |

| Hickory wood | What makes it so sustainable: Hickory is one of the strongest and hardest US hardwoods, making it a durable construction material. Hickory species grow in abundance throughout the US forests. Additionally: One cubic meter of hickory has a carbon footprint of 463 kg CO2-eq, higher than all most other commonly used US hardwoods. However, the same volume of hickory trees uptake 3,260 kg CO2-eq, resulting in a highly environmentally favorable carbon balance. |

| White oak wood | What makes it so sustainable: Back cherry wood (or American cherry) has a carbon footprint of 301 kg CO2-eq, cradle-to-gate. That is lower than all US-native hardwoods of similar density and strength. Additionally: Black cherry wood is a sustainable hardwood for construction because of the durability of the timber and the fast rate at which the cut wood is replaced in the wild. |

Overall, these woods are highly sustainable. However, the actual environmental impact of construction lumber depends on many factors, especially the distance and mode of transportation. Let’s dive deeper into each wood and the stages of its life-cycle and find out how it can be even more sustainable.

The Most Sustainable Softwoods for Construction

Softwoods are generally low in density and not as strong as most hardwoods. However, they are lighter in weight, which makes them more energy-efficient to transport. Also, some softwoods are exceptionally strong for their weight – an ideal physical property for construction lumber.

Softwood tree species tend to grow (and replenish the timber source) faster than hardwood tree species, generally making them more sustainable.

Slash Pine Wood: Exceptionally Strong Contrustrion Lumber From Fast-Growing Conifers

Slash pine (a type of southern yellow pine) is one of the most sustainable construction lumber because its exceptional strength keeps it last longer as carbon storage, extending the environmental benefit from carbon uptake during forestry. Slash pine’s fast growth rate and abundance also set it apart, in terms of sustainability, from other southern yellow pines like shortleaf species (requiring long rotations) or longleaf species (endangered species). Loblolly pine is comparable to slash pine but slightly less hard.

Here are the life-cycle stages of slash pine wood and each stage’s sustainability assessment:

- Growing of slash pine wood: Slash pine (Pinus elliottii) has a sustainable population across the southeastern US, largely thanks to the species’ fast growing rate and adaptation to even the more challenging sites. During the first 15 years, young slash pine trees can grow about three feet annually. Slash pine is, in fact, one of the fastest growing southern yellow pines.

- Manufacturing of slash pine wood: It takes 30 to 150 days to air dry green 25-mm lumber of slash pine to 20% moisture content. That is shorter than the air-drying time of some other softwoods in this list, including Douglas fir and bald cypress. The fast drying property indicates a low manufacturing carbon footprint because kiln drying is usually the most energy-intensive and carbon-heavy process for wood products.

- Transportation of slash pine wood: Slash pine trees of the two varieties, standard and south, grow within a large range across the south and the east of the US. Consequently, the transporting footprint of slash pine is relatively small, especially within the region. The standard slash pine subspecies can be found as far north as Virginia and west as Texas, while the south slash pine subspecies grow from center to south Florida.

- Usage of slash pine wood: Slash pine is a durable building material because, like all other southern yellow pine, it is hard, dense, and possesses an excellent strength-to-weight ratio. Slash pine is harder than some hardwoods like basswood or cottonwood.

Because of its strength, slash pine can be used in long-lasting structures such as beams, poles, and frames that bear a lot of weight. While slash pine lumber holds, it keeps its carbon storage role (instead of carbon dioxide being released back into the atmosphere, further warming our planet).

- End-of-life of slash pine wood: Because of slash pine’s strength, it can be used in natural form in household and construction projects. Natural pine wood can be disposed of sustainably in biomass or upcycling projects.

Slash pine and other southern yellow pines are the strongest, by quite a margin, of all US softwoods. These woods can take more bending and compression than all other softwoods, plus some hardwoods, from the US forests. Like other southern yellow pines, slash pine wood makes long-lasting material, especially in heavy construction. Thus, it stores carbon for a long time (instead of releasing carbon dioxide back into the atmosphere). Slash pine trees also grow and replenish the timber quickly, making it possible to harvest the wood without harming the forest.

Bald Cypress Wood: Durable Building Material from Adaptive Native Species

Bald cypress is a unique coniferous species that loses its needles during the winter (hence the name “bald”). These trees can thrive in wet, swampy areas throughout southeastern states.

Here are the life-cycle stages of bald cypress wood and each stage’s sustainability assessment:

- Growing of bald cypress wood: Bald cypress (Taxodium distichum) trees have a high carbon sequestration potential thanks to their large sizes: 150 feet in height and 12 feet in diameter (carbon accounts for nearly 50% of the dry weight of a tree). As bald cypress trees grow, they absorb CO2 from the atmosphere while releasing oxygen. They act as a carbon sink during their long lifespan of around 1,200 years, helping to mitigate the climate crisis.

- Manufacturing of bald cypress wood: Bald cypress is a slow-drying wood, partly due to the high moisture content of this swamp species. (The air-drying time from green to 20% moisture content is about 100 to 300 hours.) It signifies a high manufacturing footprint because kiln-drying is the most carbon-intensive step in lumber production.

- Transportation of bald cypress wood: Because bald cypress timber is light and locally available throughout the US, its transportation footprint is lower than heavy imported woods.

- Usage of bald cypress wood: Bald cypress is a long-lasting material, especially for outdoor construction projects, thanks to its decay resistance and extreme strength. The natural oils in bald cypress wood keep it at a level of rot and insect resistance similar to cedar. However, bald cypress’s bending strength is about 1,5 times higher than white cedar.

Bald cypress lumber from old-growth trees can last a few decades outside. Even cypress lumber from younger trees has a lifespan of around 20 years outdoors.

Using long-lasting softwood is sustainable because it means storing carbon in the wood for an extended amount of time.

- End-of-life of cypress wood: Because of its natural durability, the wood is seldom treated with preservatives, even for exterior usage. Thus, bald cypress lumber can be fully recycled or burned for bioenergy. Both scenarios are sustainable.

Bald cypress is a sustainable building material because it is light yet strong and has excellent resistance against elements (insects and rot). It is also locally available lumber, meaning that sourcing and transporting bald cypress have relatively low carbon footprints.

Douglas Fir: Strong Building Material From Widely Distributed Softwood Species

Douglas fir wood comes from one of the tallest tree species on the North American continent. It is also one of the best carbon capture trees on the planet, sequestering 17 pounds of carbon each and every year.

Here are the life-cycle stages of Douglas fir wood and each stage’s sustainability assessment:

- Growing of Douglas fir wood: The high carbon sequestration potential makes growing Douglas firs for timber sustainable. This tree species (Pseudotsuga menziesii) can grow as tall as 250 feet and as big as six feet in diameter in old-growth forests. The record for Douglas fir height is 330 feet, more than double the height of a tall black walnut tree. The annual growth rate of Douglas fir is up to 2 feet, higher than that of most hardwood species.

- Manufacturing of Douglas fir wood: Douglas fir lumber can be air-dried from green to a 20% moisture content. The drying time varies significantly depending on the season and location (20 to 200 hours). Using a kiln takes about 32 hours to dry 1/8 inch-sized Douglas fir lumber from green to 15% moisture content.

- Transportation of Douglas fir wood: Douglas fir trees are distributed widely in the US: they populate the largest section of western states. Consequently, transporting carbon footprint is relatively low, especially compared with imported hardwoods for construction like teak or mahogany.

- Usage of Douglas fir wood: Douglas fir is one of the strongest western softwood species. It is twice as hard per square inch as cedar and, thus, a possibly longer-lasting choice for heavy construction. The longer floors last, the more sustainable they are because they store carbon instead of releasing it back to the atmosphere.

- End-of-life of Douglas fir wood: The end-of-life stage for Douglas fir is sustainable when the wooden structures are reused or burned as bioenergy.

Douglas fir is a beautiful and long-lasting softwood for your building your home. These fast-growing, towering conifers account for a fifth of North America’s total softwood reserves – a healthy and sustainably managed stock for timber harvesting. It is a particularly hard softwood with a high strength-to-weight ratio and some resistance to decay.

Sitka Spruce Wood: Locally Available Construction Lumber From Fast-Growing Conifers

Sitka spruce has an excellent strength-to-weight ratio, making it a durable softwood for applications requiring strong yet light material. Plus, Sitka spruce trees grow in abundance in the US forests.

Here are the life-cycle stages of Sitka spruce wood and each stage’s sustainability assessment:

- Growing of Sitka spruce wood: Sitka spruce (Picea sitchensis) is one of the fastest-growing tree species in North America. In ideal conditions, young trees’ height may increase by 5 feet yearly. They also grow large and tall: a Sitka tree can weigh more than 300 tons and have an impressive height of 300 feet. Their size signifies a high carbon sequestration potential as carbon accounts for nearly 50% of the dry weight of a tree.

- Manufacturing of Sitka spruce wood: Sitka spruce dries fairly quickly: air-drying green 1-inch lumber of Sitka spruce to a 20% moisture content takes 40 to 150 days. Fast-drying wood tends to have a lower manufacturing carbon footprint because kiln-drying is the most carbon-intensive step in lumber production.

- Transportation of Sitka spruce wood: Thanks to the abundance of Sitka spruce in the US, the transport footprint of this softwood lumber is lower than imported hardwoods.

- Usage of Sitka spruce wood: Sitka spruce has an outstanding stiffness-to-weight ratio. Thus, it is a long-lasting material for construction projects like residential housing frames.

- End-of-life of Sitka spruce wood: The end-of-life stage of Sitka spruce is sustainable when the wood is upcycled for other projects or burned for bioenergy.

Spruce is highly available, thanks to the large population, the quick growth, and the enormous tree size. The excellent strength-to-weight ratio of Sitka spruce is behind its durability. This construction timber can last many years, keeping their carbon storage role. Also, Sitka spruce dries quickly, resulting in a relatively low manufacturing carbon footprint.

Nootka Cypress Wood: Strong and Decay-Resistant Softwood for Construction

Nootka cypress wood comes from medium-size, long-lived conifers native to the west coast of North America. This Cupressus nootkatensis species belongs to the Cypress family but is also commonly called a cedar, as in Alaska yellow cedar or yellow cedar.

Here are the life-cycle stages of Nootka cypress wood and each stage’s sustainability assessment:

- Growing of Nootka cypress wood: As Nootka cypress (Cupressus nootkatensis) trees grow, they absorb CO2 from the atmosphere while releasing oxygen. They act as a carbon sink during their long lifespan. Nootka cypress can live as long as 3,500 years.

As a carbon sink, Nootka cypress trees pull greenhouse gasses out of the atmosphere, helping to mitigate the climate crisis. Trees store as much carbon as 50% of their dry weights. Thus, a tree stores more carbon as it grows taller and bigger. Nootka cypress trees can reach 120 feet in height.

- Manufacturing of Nootka cypress wood: Nootka cypress is stable wood with little tendency to warp and check while drying. It takes four and a half days to kiln dry 1-inch timber to a 7% moisture content.

- Transportation of Nootka cypress wood: Along the west coast, it’s possible to source Nootka cypress wood at a relatively short distance, lowering the transportation footprint.

- Usage of Nootka cypress wood: Nootka cypress is highly durable, thanks to the heartwood’s chemical compounds that inhibit fungal growth. It has excellent decay resistance and is also resistant to most insect attacks. Regarding strength, it is among the strongest US softwoods (comparable to Douglas fir), making it an long-lasting material for siding, flooring, decking and other construction applications.

- End-of-life of Nootka cypress wood: Because of its natural durability, the wood is seldom treated with preservatives, even when in contact with the ground. Thus, Nootka cypress wood products can be fully recycled or burned for bioenergy. Both scenarios are sustainable.

Nootka cypress is a sustainable softwood for construction because of its excellent stability, strength, and decay resistance. Siding or decking made with this material can last for a long time, keeping the role of carbon storage.

Western Red Cedar Wood: Light and Water-Resistant Construction Lumber

Western red cedar is timber from the tall and big conifers that grow in abundance in the US – the giant arborvitae. Also, cedar timber has a relatively low transporting carbon footprint because it is light and available locally within the US.

Here are the life-cycle stages of western red cedar wood and each stage’s sustainability assessment:

- Growing of western red cedar wood: Western red cedar (Thuja plicata) trees have a high carbon sequestration potential, thanks to their large sizes (200 feet in height and 4 feet in diameter) and their long lifespan (over 1,000 years). In North America, western red cedar trees are abundant and sustainably managed. Thus, timber harvesting doesn’t harm the forests.

High carbon uptake during this stage can compensate fully for carbon emissions throughout the whole life-cycle, meaning that western red cedar product can have a negative carbon balance. For example, the net carbon balance of 100 square feet of no-stain western red cedar decking is -13.39 kg CO2-eq (cradle-to-grave).

- Manufacturing of western red cedar wood: Western red cedar is dimensionally stable; thus, less energy is wasted on shrinkage, checking, and warping during kiln-drying.

- Transportation of western red cedar wood: Western red cedar trees are abundant in the Northwest US. In states such as Washington, Oregon, or Idaho, it’s possible to source western red cedar locally, lowering the transportation footprint. Also, transporting this lightweight timber is more fuel-efficient than hauling heavy hardwoods. Consequently, transporting carbon footprint per unit is smaller. In a case study, the carbon footprint of transporting 100 feet of western red cedar decking panels to customers within Minneapolis is 18.25 kg CO2-eq.

- Usage of western red cedar wood: Western red cedar is relatively soft and prone to dent. However, western red cedar is rated as durable to very durable regarding decay resistance, making it an ideal material for outdoor building elements like shingles and exterior siding.

While western red cedar lumber holds, it keeps its carbon storage role (instead of carbon dioxide being released back into the atmosphere, further warming our planet).

- End-of-life of western red cedar wood: The end-of-life stage for western red cedar as construction lumber is sustainable because the wood can be fully reused or burned as bioenergy.

Western red cedar is a sustainable material because of its carbon sequestration potential. Also, this light and abundant timber is easy to source and low energy-consuming to transport. Its natural resistance to decay makes it a durable material for construction lumber in contact with outdoor elements.

Western Larch Wood: Strong Softwood From Rapid-Growing Coniferous Species

Western larch wood comes from deciduous conifers, also called tamarack and western tamarack. This softwood species grow rapidly, replenishing timber at a fast rate – a telltale sign of its sustainability.

Here are the life-cycle stages of western larch wood and each stage’s sustainability assessment:

- Growing of western larch wood: Western larch (Larix occidentalis) is a rapidly growing conifer. The seedlings of western larch species grow three times faster than Douglas fir seedlings and four times faster than Engelmann spruce. In the first 100 years, western larch trees have the highest annual height increase among all conifers growing naturally in the Northern Rockies.

Consequently, western larch timber stock can be replenished quickly, making sustainability more attainable.

- Manufacturing of western larch wood: Western larch dries fairly quickly: air-drying green 1-inch lumber of western larch spruce to a 20% moisture content takes 60 to 120 days. Fast-drying wood tends to have a lower manufacturing carbon footprint because kiln-drying is the most carbon-intensive step in lumber production.

- Transportation of western larch wood: Western larch has a relatively limited natural range: southeastern British Columbia, central to northern Idaho, western Montana, and northeastern Washington. Consequently, transportation footprint is relatively small within the northern states, and higher for the southern states.

- Usage of western larch wood: Western larch is one of the hardest softwoods in the United States, with a Janka hardness of 830 lbf—about as hard as American elm. Its hardness makes it an long-lasting construction lumber.

- End-of-life of western larch wood: The end-of-life stage of western larch is sustainable when the wood is upcycled for other projects or burned for bioenergy.

Western larch is sustainable construction lumber, especially within its natural range. Western larch trees grow more rapidly than any conifers in the Northern Rockies. Besides, its high density and hardness make it more durable in building projects than many other softwoods.

The Most Sustainable Hardwoods for Construction

Hardwood lumber tends to last longer than softwood lumber in structures that bear heavy weights because hardwoods tend to have higher density and strength. Their durability is the telltale sign of their sustainability because the longer construction lumber last, the longer the carbon captured by timber trees stays out of the atmosphere.

Black Cherry Wood: Durable Hardwood from Fast-Growing Trees

Black cherry is a sustainable hardwood for construction because of its short rotation for harvesting and its low carbon footprint. On a life-cycle assessment, cradle to gate, black cherry wood has a carbon footprint of 301 kg CO2-eq – lower than all US-native hardwoods of similar density and strength.

Here are the life-cycle stages of black cherry wood and each stage’s sustainability assessment:

- Growing of black cherry wood: Black cherry trees grow at fast rates of 2 to 4 feet per year. They act as a carbon sink during their long lifespan, helping to mitigate the climate crisis.

- Manufacturing of black cherry wood: Kiln drying 1-inch-thick black cherry lumber takes up to 120 hours and has a relatively low carbon footprint of 42.7 kg CO2-eq. Manufacturing carbon emission of black cherry is similar to willow wood and smaller than many other dense hardwoods like hard maple, hickory, red oak, and white oak.

- Transportation of black cherry wood: Black cherry grows abundantly in the wild throughout the US, resulting in a lower transporting carbon footprint. Thus, it is a sustainable alternative to imported tropical woods like mahogany.

- Usage of black cherry wood: Black cherry construction lumber is long-lasting carbon storage because the wood is resistant to decay and weather changes. Regarding usage, it is a very sustainable option, more so than hardwoods like maple.

- End-of-life of black cherry wood: The end-of-life stage for black cherry lumber is sustainable when the wood is reused or burned as bioenergy.

Black cherry (or American cherry) wood is a sustainable hardwood for construction because of the durability of the timber and the fast rate at which the cut wood is replaced in the wild.

Black Locust Wood: Fast-Growing Hardwood Species for Durable Construction Lumber

Black locust is one of the most adaptable and easy-to-grow trees. Though it is grown more as an ornamental than a commercial timber tree, its wood is particularly durable as exterior lumber.

Here are the life-cycle stages of black locust wood and each stage’s sustainability assessment:

- Growing of black locust wood: Black locust (Robinia pseudoacacia) is a fast-growing hardwood species with an annual growth rate of 2 feet. Seedlings grow more rapidly, up to 4 feet per year (and post-cutting sprouts grow even faster). Because the forests can replenish relatively quickly, timber harvesting is fairly sustainable.

- Manufacturing of black locust wood: Black locust dries very slowly. That signifies a high manufacturing footprint because kiln-drying is the most carbon-intensive step in lumber production.

- Transportation of black locust wood: Because black locust is a domestic wood, its transporting footprint is lower than imported hardwoods like mahogany or meranti.

- Usage of black locust wood: Black locust is very strong. Its strength exceeds teak, most oak species, and is comparable to hickory. Besides, it’s very durable with good weathering characteristics thanks to high rot resistance and stability (once dried). Thus, exterior structures like fence posts made with black locust have a very long lifespan (50 years and more).

- End-of-life of black locust wood: Thanks to its natural rot resistance, there is no need to use chemical treatment for black locust for building exterior structures. Thus, at the end of life, black locust lumber can be fully recycled, upcycled, or burned as bioenergy.

Black locust is one of the most sustainable hardwoods for constructing exterior structures, thanks to its fast-growing nature and high outdoor performance. This tree species grows fast and can regrow even more rapidly after cutting, replenishing timber cut for woodworking. Exterior structures made with black locust can last for many decades, extending their role as carbon storage.

Hickory Wood: Strong and Water-Resistant Hardwood for Construction

Hickory is one of the strongest and hardest US hardwoods. Building structures made with hickory require little maintenance and are water and scratch-resistant. Hickory species grow in abundance throughout the US forests.

Here are the life-cycle stages of hickory wood and each stage’s sustainability assessment:

- Growing of hickory wood: As hickory trees (genus Carya) grow, they absorb CO2 from the atmosphere while releasing oxygen. They act as a carbon sink during their long lifespan (up to 500 years).

It takes only 4.33 seconds to replace 1m³ of hickory lumber in the US forests because of these species’ large population. Hickory trees account for 4.7% of US hardwood growing stock and yearly growth exceeds harvest in all significant producing states. Thus, it is possible to harvest timber without harming the forests.

- Manufacturing of hickory wood: Kiln drying hickory has a carbon footprint of 42.7kg CO2-eq (one cubic meter of 1-inch hickory logs), slightly higher than hard maple but lower than other popular hardwoods for construction like oak and walnut.

- Transportation of hickory wood: Hickory trees grow naturally throughout the Eastern US, from north to south. Thus, hickory lumber would have a lower transportation footprint than imported hardwoods like merbau or padauk.

- Usage of hickory wood: A hickory structures can last for decades, keeping its role as carbon storage. These species have high Janka scores, indicating good strength and hardness. Also, hickory wood is water resistant, ideal for buildings in regions with high humidity.

- End-of-life of hickory wood: The end-of-life stage for hickory lumber is sustainable when the wood can be reused for another woodworking project or burned as bioenergy.

One cubic meter of hickory has a carbon footprint of 463 kg CO2-eq, higher than almost all other commonly used US hardwoods. However, the same volume of hickory trees uptake 3260 kg CO2-eq, resulting in a highly environmentally favorable carbon balance.

White Oak Wood: Durable Hardwood From Highly Sustainably Managed Stock

One cubic meter of white oak has a carbon footprint of 556 kg CO2-eq, higher than all other commonly used US hardwoods. However, the same volume of white oak trees uptake 3200 kg CO2-eq, resulting in a highly environmentally favorable carbon balance.

Here are the life-cycle stages of white oak wood and each stage’s sustainability assessment:

- Growing of white oak wood: The white oak (Quercus rubra) accounts for 15.5% of US hardwood growing stock. That is, for example, more than three times the growing volume of hickory. Because of the large population of white oak trees, it takes merely 1.57 seconds for the US forests to grow 1m³ of white oak. Though this hardwood species has a slow growth rate, such a growing stock allows harvesting timber without harming the forests.

- Manufacturing of white oak wood: Kiln drying white oak has a carbon footprint of 98.3 kg CO2-eq (one cubic meter of 1-inch white oak logs). As white oak species dry slowly, they tend to have a high manufacturing footprint because kiln-drying is the most carbon-intensive step in lumber production.

- Transportation of white oak wood: Because white oak trees are widely distributed throughout most eastern states, it is possible to source this timber at relatively short distances. white oak lumber would have a lower transportation footprint than, for example, teak lumber imported from South East Asia.

- Usage of white oak wood: White oak is generally water-tight thanks to the presence of tyloses in its “pores.” These cells prevent white oak wood from wicking up water and rotting. Tyloses also help protect the timber from insects. Thus, white oak is a highly durable exterior material. Its heartwood has a similar outdoor lifespan as western cedar (up to three decades).

- End-of-life of white oak wood: The end-of-life stage for white oak lumber is sustainable when the wood can be reused for another woodworking project or burned as bioenergy.

White oak is one of the most sustainable woods for outdoor structures, thanks to its natural durability and the high volume of white oak trees. It is a strong and stable wood with high water resistance. Thus, your outdoor structures last for decades through rain and snow.

Tropical Hardwoods for Construction: A Few Words on Their Sustainability

Some tropical hardwoods are long-lasting construction materials thanks to their hardiness and natural resistance to decay. However, they come from tropical rainforests where illegal logging has devastating consequences on the earth’s biodiversity.

Some highly prized tropical hardwoods for construction include:

Though the durability of these hardwoods is a big contribution to their overall sustainability as a construction material, there are two other factors:

- Eco costs of logging

- Transportation distances

Firstly, it is possible to source tropical hardwoods that are sustainably harvested. There are certificates such as FSC and PECC, which guarantee sustainable forestry management. In that case, the eco costs of such hardwoods can be lower than woods that might require treatment to last equally long.

Providing that you can find FSC-certified tropical hardwoods, the distances and the mode of transport still affect the total carbon emissions.

The transporting footprint of these hardwoods is undoubtedly higher than woods sourced locally in the US.

In brief, tropical hardwoods are not as environmentally friendly as untreated softwoods and hardwoods available locally within the US.

However, suppose you want floors made with naturally durable, beautiful tropical hardwoods, you should search for the most sustainable options in this group:

- You should watch out that they have a sustainable certificate, such as FSC or PECC. You need to avoid timber associated with deforestation in tropical rainforests – the world’s most biodiverse places.

- Traveling distance matters. You should weigh all your options and go for the woods that travel the least.

- It would also be an environmentally friendly option if you can find salvaged or recycled tropical hardwoods.

Engineered Wood for Construction: A Few Words on Their Sustainability

Engineered (composite) wood panels have become a popular choice for construction because of their low maintenance and wood-alike look. Besides, they can be made with wood waste from fast-growing, easily replenished species like cypress, pine, or hemp. It is an environmentally favorable factor compared to using slow-growing hardwoods.

Besides, engineered wood is less susceptible to swelling and warping from moisture and heat. Consequently, plywood panels, for example, can be a longer-lasting option than some solid woods for constructing structures in high humidity regions.

Yet, some composite panels are more environmentally friendly than others. If you decide to go on this path, make sure your construction material has the highest recycled content and that the resins used are safe for the environment and, if possible, biodegradable.

How Can You Buy More Sustainable Wood

The key to sustainably buying any wood is to check on relevant environmental and original certifications. Reliable certifications for sustainable woods are:

An FSC certification ensures that the ash wood comes from responsibly managed forests that provide environmental, social, and economic benefits.

There are three levels of FSC certifications (FSC 100%, FSC Mix, FSC Recycled). Ideally, opt for FSC 100% or Recycled.

PEFC’s approaches to sustainable forest management are in line with protecting the forests globally and locally and making the certificate work for everyone. Getting a PEFC certification is strict enough to ensure the sustainable management of a forest is socially just, ecologically sound, and economically viable but attainable not only by big but small forest owners.

Why Is It Important to Buy More Sustainable Wood

Improperly managed logging (including illegal activities) can cause many problems for forest equality and diversity. One example is when loggers only cut down the biggest and tallest trees. That pattern would cause a reduction in the genetic diversity and quality of the trees within the stand, leading to gradual degradation of tree quality.

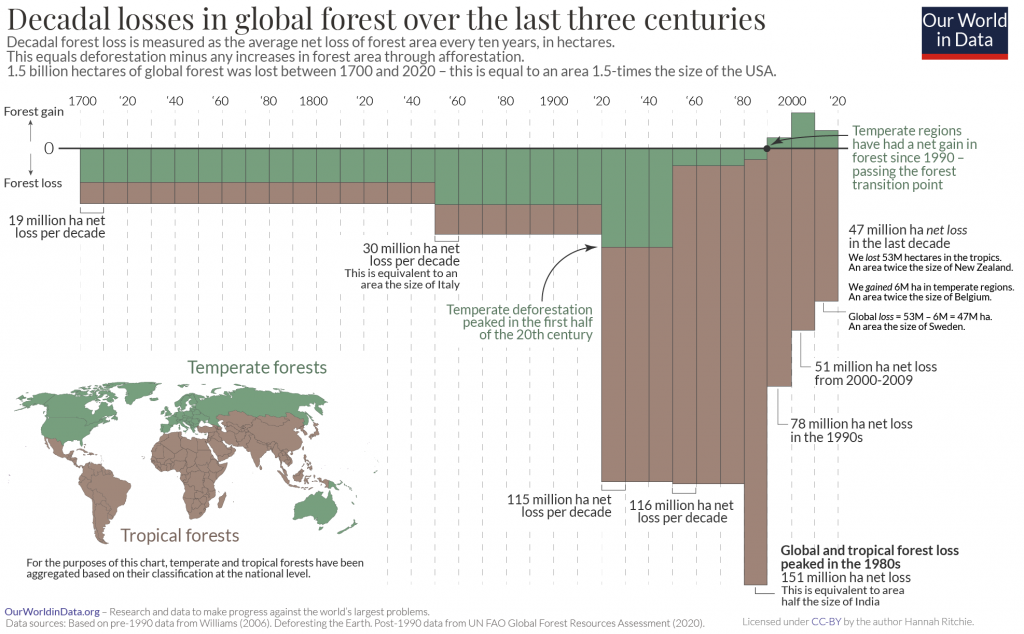

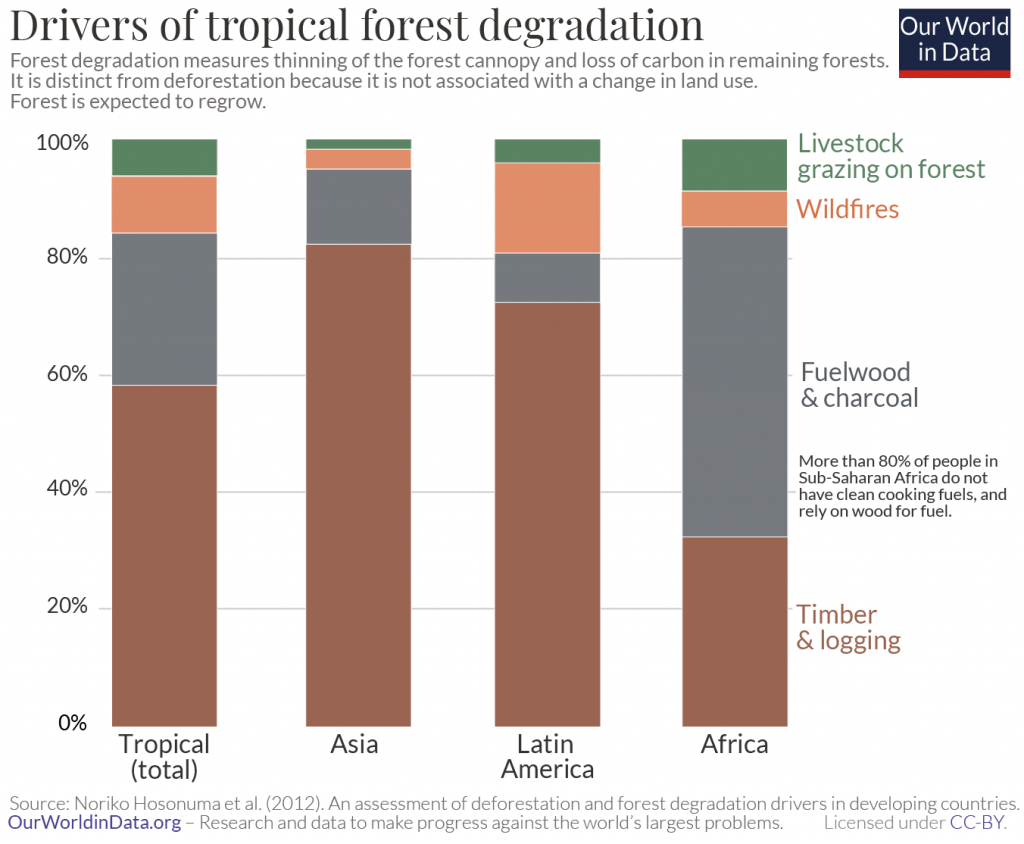

In total, logging of forestry products from plantations accounts for 26% of forest loss, which is a combination of deforestation and forest degradation. However, the loss in bio-diverse forests in tropical climates is more significant (and sometimes less properly recorded) than in temperate, well-managed logging forests.

Buying sustainable wood also means helping to prevent illegal or unsustainable logging, which harms the forests’ biosystems and accelerates climate change.

Cutting down trees for wood has a lesser impact on carbon storage than digging up the whole forest floor and turning it into farms or mines. However, if logging is not sustainably managed, it can badly damage wildlife.

When logging happens in tropical forests – the bio hotspots of our planet – the biodiversity loss can be much more damaging. Subtropical and tropical forests are packed with unique wildlife – endemic mammals, birds, and amphibians. The displacement of such wildlife during poorly managed logging would be a major contributor to global biodiversity loss.

Sustainable management of forests also means that trees are cut down for timber only when they are mature. These trees will then be able to regrow and eventually replace the loss of canopy, absorb carbon from the atmosphere and reduce the effect of climate change.

Final Thoughts

You can source sustainable woods for building your home from sustainably managed forests. Slash pine, bald cypress, and Douglas fir are fast-growing softwood species with natural durability suitable for construction. Also, hardwoods like white oak and black cherry make durable and beautiful structures for your home. There are also sustainable options for construction coming from wood-like materials or engineered woods. More importantly, you can make it more sustainable by using these wooden structures for as long as possible. Then, look into upcycling the material to extend its usage and/or arrange for it to be recycled fully.

Stay impactful,

Sources

- Science Direct: Life-cycle assessment (LCA)

- MIT SMR: Strategic Sustainability Uses of Life-Cycle Analysis

- European Environment Agency: Cradle-to-Grave

- Science Direct: Cradle-to-Gate Assessment

- Impactful Ninja: How Sustainable Is Engineered (Composite) Wood? Here Are the Facts

- Impactful Ninja: How Sustainable Is Pine Wood? Here Are the Facts

- Impactful Ninja: How Sustainable Is Cypress? Here Are the Facts

- Impactful Ninja: How Sustainable Is Douglas Fir Wood? Here Are the Facts

- Impactful Ninja: How Sustainable Is Spruce? Here Are the Facts

- Impactful Ninja: How Sustainable Is Cedar Wood? Here Are the Facts

- Impactful Ninja: How Sustainable Is Black Cherry Wood? Here Are the Facts

- Impactful Ninja: How Sustainable Is Hickory Wood? Here Are the Facts

- Impactful Ninja: How Sustainable Is White Oak Wood? Here Are the Fact

- THE WOOD DATABASE: SLASH PINE

- US Forest Service: Growth and Yield of Slash Pine Plantations

- U.S FOREST SERVICE: Air Drying Lumber

- Impactful Ninja: How Sustainable Is Basswood? Here Are the Facts

- THE WOOD DATABASE: BALD CYPRESS

- Cypress Info: Why Harvesting Cypress is Essential

- U.S FOREST SERVICE: SPECIES: Taxodium ascendens, T. distichum

- U.S FOREST SERVICE: Air Drying Lumber

- HAND TOOL ESSENTIALS: Bending Strengths of North American Softwood

- TREE PLANTATION: A Douglas Fir Tree Is One Of The Best Carbon Sequestration Trees On The Planet

- THE WOOD DATABASE: DOUGLAS-FIR

- UNIVERSITY OF CALIFORNIA: Douglas-fir

- Impactful Ninja: How Sustainable Is Black Walnut Wood? Here Are the Facts

- US Forest Service: KILN DRYING DOUGLAS FIR COMMON LUMBER

- Impactful Ninja: How Sustainable Is Teak Wood? Here Are the Facts

- Impactful Ninja: How Sustainable Is Mahogany Wood? Here Are the Facts

- AMERICAN SOFTWOODS: DOUGLAS FIR

- THE WOOD DATABASE: SITKA SPRUCE

- ACADEMIA: An Environment in Tonewoods

- THE WOOD DATABASE: ALASKA YELLOW CEDAR

- U.S FOREST SERVICE: SPECIES: Callitropsis nootkatensis

- U.S FOREST SERVICE: SPECIES: Alaska-Cedar

- U.S FOREST SERVICE: SPECIES: Thuja plicata Dpmm ex D. Don

- THE WOOD DATABASE: WESTERN RED CEDAR

- FPInnovations: Typical Western Red Cedar Decking

- THE WOOD DATABASE: WESTERN LARCH

- US Forest Service: Western Larch

- THE WOOD DATABASE: JANKA HARDNESS

- PE INTERNATIONAL: Life Cycle Assessment of Rough-sawn Kiln-dried Hardwood Lumber

- Impactful Ninja: How Sustainable Is Willow Wood? Here Are the Facts

- Impactful Ninja: How Sustainable Is Red Oak Wood? Here Are the Facts

- THE WOOD DATABASE: BLACK LOCUST

- U.S FOREST SERVICE: Black Locust

- Impactful Ninja: How Sustainable Is Meranti Wood? Here Are the Facts

- HuGBC: Black Locust as sustainable choices in green building

- Britannica: hickory

- American Export Hardwood Council: American Hickory

- Impactful Ninja: How Sustainable Is Maple Wood? Here Are the Facts

- Impactful Ninja: How Sustainable Is Merbau Wood? Here Are the Facts

- Impactful Ninja: How Sustainable Is Padauk Wood? Here Are the Facts

- American Export Hardwood Council: White Oak

- THE WOOD DATABASE: WHITE OAK

- Britannica: Organization of the vascular tissue

- Nordic Ecolabelling: Durable/resistant wood for outdoor use

- Impactful Ninja: How Sustainable Is Ipe Wood? Here Are the Facts

- Forest Stewardship Council

- Program for Endorsement of Forest Certification

- Impactful Ninja: How Sustainable Is Plywood? Here Are the Facts

- Impactful Ninja: How Sustainable Is Wood Plastic Composite? Here Are the Facts

- Our World in Data: Deforestation and Forest Loss

- Our World in Data: Epidemic Mammal Species